Metal Cutting

Water Jets can cut through metals up to 200mm thick. This is done by propelling water up to 2000mph through rigid, high pressure hoses and jets at a pressure of up to 60,000PSI, these jets can contain abrasive substances, such as garnet which erode away the material. Jet cutters have no problem slicing though Stainless Steel, Titanium, Tool Steel or even Armour Plating. Water cutting is typically used for cutting, excision or ablation (removing parts); structuring and can lend it to cutting items with sandwich structures or have a combination of materials.

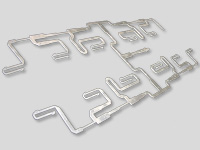

Below is an example of the excellent lines that can be created through the use of water jet cutting:

10mm thick S/Steel component |

4mm thick Titanium baffle plate |

Intricate detail in 1.5mm thick Aluminium for Radar application |

50mm thick Aluminium Machine End plate |